Aquarium water pumps move water through your tank, providing the circulation that keeps fish, invertebrates, and aquatic plants alive. Every living thing in an aquarium depends on water flow — fish need it for oxygen and food delivery, plants need it for nutrient exchange, and beneficial bacteria need it to process ammonia, nitrite, and organic waste.

Understanding the components of an aquarium water pump

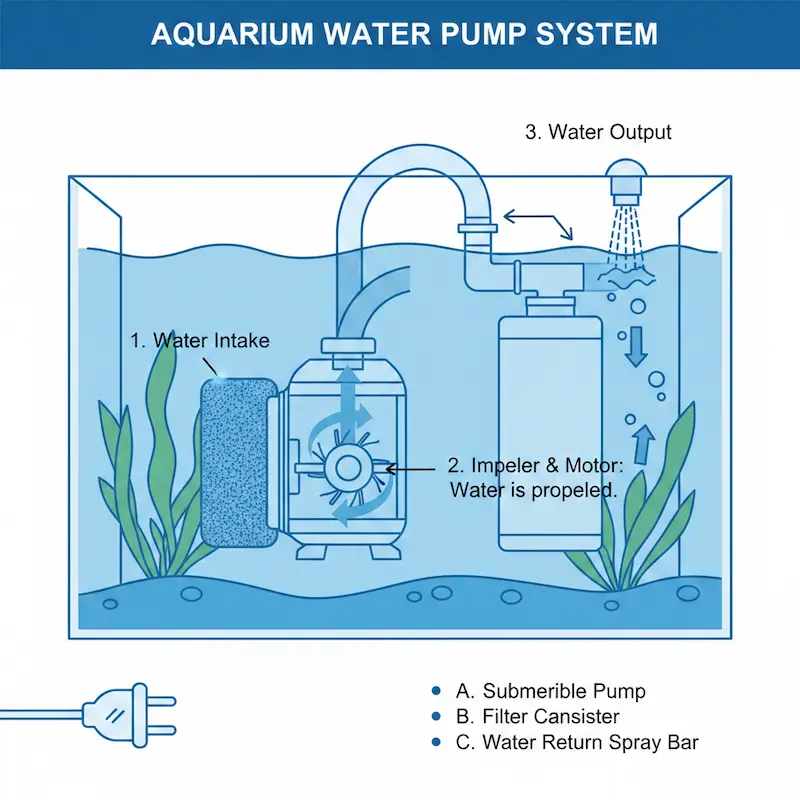

Aquarium water pumps work by spinning an impeller inside an enclosed pump head. The spinning impeller pulls water in through an intake port, transfers kinetic energy to the water via centrifugal force, and forces pressurized water out through a discharge outlet. The motor type (AC or DC), drive method (direct or magnetic), and impeller size determine how much water the pump can move and at what pressure.

Corals and other marine filter-feeders depend on water flow to bring in nutrients and flush away waste products. Aquarium filters capture debris and adsorb chemical wastes by pumping water through filtration media. Today’s aquarist has a wide variety of aquarium-specific water pumps to choose from, but not all of them work the same way.

Water Pump Basics

Aquarium water pumps are equipment designed and sold specifically for aquarium filtration and water circulation. The three main categories are return pumps, filter pumps, and wave-making pumps. All of these pump categories share several features in common.

The Heart of Every Pump

At the heart of every pump is the impeller - a spinning component that moves water through centrifugal force.

The impeller moves the water through centrifugal force. There are several impeller designs but all have some kind of straight or curved vanes. Some impellers are sandwiched between two solid plates (closed) or semi-open with only one plate.

The impeller is attached to a spinning shaft, driven by an electric motor. But it’s not that simple. Simply spinning the impeller will just create a lot of churning water that goes nowhere. In order to move water, the laws of physics must be obeyed!

The spinning impeller must be surrounded in an enclosure to focus the energy the impeller gives to the water. As the impeller spins, water is pulled into the intake port. Kinetic energy from the spinning impeller is transferred to the water. The energized water is forced to the sides of the pump enclosure, which builds pressure.

The enclosure or “pump head” is designed to guide the pressurized water out of the head through the discharge outlet. This is how a pump pressurizes and moves water.

Pump Motors and Impellers: Size Matters

Aquarium pumps come in different sizes and flow rates. In its most basic form, an aquarium water pump has a fixed RPM, non-adjustable electric motor. Most fixed-speed pumps operate at either 1,750 or 3,500 RPM.

Understanding Flow and Energy

The faster the impeller turns the more energy is transferred to the water. Increasing the size of the impeller also increases energy transfer.

A typical aquarium water pump — the impeller spins inside the enclosed pump head to move water

The pump impeller creates flow, not pressure. The pump head design adds a restriction that creates the actual pressure inside the pump. The pressurized water is forced out of the pump and into the aquarium or through a filter.

The design of the head casing, motor RPM and the impeller creates the pressure required to push the water from one place to another. The laws of physics put limits on how much water a pump can move. A tiny pump will never be able to move as much water volume as a large pump.

Direct Drive vs Magnetic Drive

Aquarium water pumps use one of two methods to transfer motor torque to the impeller: direct drive or magnetic drive.

Direct Drive

Direct drive physically connects the motor shaft to the impeller. A shaft seal prevents water from leaking from the pump housing. Direct drive pumps are built primarily for pushing water against resistance.

Direct drive pumps excel when water is pumped through large pressurized filter systems or multiple large canisters. Pumping water a long distance or to great heights is the job of high-torque, direct drive water pumps.

When to Choose Direct Drive

- Pumping water through large pressurized filter systems

- Moving water long distances or to great heights

- Pushing large volumes of water per hour

- Working with multiple canister filters

Magnetic Drive

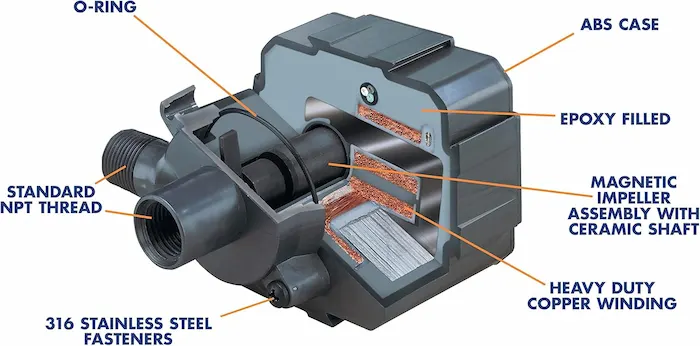

Magnetic drive pumps isolate the pump motor from the impeller and casing. The impeller is enclosed in the pump casing, completely isolating the electric motor from the aquarium water. Strong magnets attached to the pump shaft and impeller make the connection and spin the impeller.

Inside a magnetic drive pump — magnets transfer motor torque to the impeller without a physical shaft connection

Mag drive pumps are very popular with aquarists. Because mag drive pumps don’t have a “wet shaft” there is no chance of a failed shaft seal causing a leak.

Direct Drive vs Magnetic Drive: Quick Comparison

| Direct Drive | Magnetic Drive | |

|---|---|---|

| Motor Connection | Physical shaft to impeller | Magnets through sealed housing |

| Pressure Output | High — built for resistance | Moderate — best for open flow |

| Leak Risk | Possible if shaft seal fails | No shaft seal — no leak risk |

| Best For | Canister filters, long runs, high lifts | Sumps, return pumps, general use |

| Noise Level | Moderate to high | Low — fewer moving parts |

| Maintenance | Shaft seal requires inspection | Minimal — replace impeller/magnets as needed |

| Cost | Higher — more complex motor | Lower — simpler construction |

Variable Speed Water Pumps

The flow rate of traditional fixed RPM water pumps is controlled by throttling back the water with a valve. It can be argued that you’re not really “controlling” the flow, just restricting it. This wastes energy since the pump motor is working to push water against the partially closed valve.

Modern Flow Control

Variable flow aquarium pumps are now available that allow you to have full control of the water output of the pump without wasting energy.

Regular water pumps run on AC current. The newer controllable water pumps run on DC current. Low-voltage DC water pumps use less electricity compared to traditional AC-powered water pumps. DC water pumps run cooler and transfer less heat to the aquarium.

DC Pump Advantages

- Smaller size than traditional AC water pumps

- Precise flow control with wired pad or wireless app

- Lower electricity usage and cooler operation

- Low-voltage is safer around water

- Built-in flow modes for tides, surges, and slack times

- Ideal for protein skimmers with needle wheel impellers

DC water pumps are used primarily as return pumps for circulating water through a sump and back into the tank. They are built for efficient water flow and low power usage in a low-pressure environment.

Some DC return pumps have built-in flow modes. The pump will create tide patterns, surges and even slack times, just like in nature. Their precise flow control and small size make DC water pumps ideal for running a protein skimmer too. DC pumps paired with needle wheel impellers chop air into microscopic bubbles, creating the dense foam that protein skimmers need to pull dissolved organic compounds from saltwater.

Internal vs External Aquarium Pumps

Aquarium water pumps fall into two installation categories: external pumps that sit outside the tank and submersible pumps that operate underwater.

External Pumps

External pumps are not waterproof and should not be exposed to water spray or drips. The most common use of external pumps is connected to a filter sump. The water pump intake is positioned below the water level in the sump. A bulkhead fitting with solid or flexible tubing is used to join the pump to the sump. Freestanding external pumps are also used with pressurized canister filters and for water recirculation.

Submersible Pumps

Submersible pumps are designed to be completely submerged in water. The pump motor and electrical connections are waterproof.

Avoid Oil-Filled Pumps

Oil-filled submersible pumps contain mineral oil as a motor lubricant. While mineral oil is not inherently toxic, a leak can ruin the aquarium. There is no reason to use an old-fashioned oil-filled water pump today.

Aquarium pump manufacturers have created a variety of fully submersible, oil-free water pumps. The Fluval Sea SP6 Sump Pump is one example of a dedicated submersible sump pump designed for reef filter systems. Submersible pumps are easy to use — just drop the pump into the sump and connect a return hose.

Some of the newer DC water pumps can be used externally or submerged. The CURRENT USA eFlux DC Flow Pump, for instance, offers a 635–3,170 GPH flow range and works in both submersible and external configurations. These dual-use pumps come with high-quality friction slip-fittings for PVC pipe and adapters, making external hook-up quick and easy. The friction fittings are easy to loosen and disconnect so pump removal is easy too.

Easy disassembly matters because all aquarium water pumps need periodic cleaning to maintain flow. These cool-running DC motors can be controlled with an app or a wired control pad.

With the popularity of nano and small reef aquariums, compact DC water pumps are ideally suited for nano under-tank sump filter systems. Internal All-In-One aquarium filters can be upgraded with compact DC water pumps too. Most AIO filters come with budget AC submersible pumps. A fully controllable DC pump is a retrofit that cuts electrical usage and heat transfer to the aquarium.

Powerheads and Wave Makers

Powerhead pumps use a simplified motor design built for continuous water circulation. A series of wire coils, encased in epoxy, make up the bulk and weight of the powerhead. When plugged in, the wire coils create an electric field.

A magnet-encased impeller sits inside the electric field, supported by an axel shaft. The electric field causes the magnet to spin, turning the impeller. The only moving part is the impeller, which turns on the shaft. This simplified water pump works well for continuous water pumping. Water flow rate is determined by the size of the coil and impeller.

Newer DC wave-making pumps place the electric motor outside of the aquarium glass. The motor and impeller are magnetically coupled through the glass. The external motor eliminates heat transfer to the aquarium water and takes up less space than bulky traditional powerheads. Proper circulation pump placement is essential to getting the most out of these wave makers.

DC Wave Maker Features

- Fine-tune flow rate for corals, plants, and delicate fish

- Built-in flow modes that mimic tides, waves and currents

- Automatic speed changes for natural ebb and flow

- Feeding mode that temporarily shuts down the pump

- Wireless control through cloud and app features

- Soft start-ups that prevent impeller chattering

DC pump design allows for soft start-ups where impeller speed gradually increases when switched on. AC powerheads do not work well as intermittent surge or wavemakers. When AC current is switched on, the magnetic impeller can spin forward or backward depending on its position in the electrical field, creating a loud chattering noise. DC pumps don’t suffer from this problem — the smooth, precise start-ups allow DC water pumps to create the smooth rolling waves and lagoon currents they’re known for.

Pump Flow Rates and Specifications

Aquarium water pump flow rates decrease as pumping height increases. Gravity and friction inside the pipe, tubing, and valves all resist the flow of water. The higher a pump needs to push water, the less volume it can deliver.

Understanding Head Pressure

This resistance is called “head.” The higher the head, the less flow you’ll get out of a pump. Always check flow charts for actual output at your required height.

Water pump flow rates can be deceiving. The flow rate stated on the package or specification page is usually the maximum flow rate with no resistance to flow.

Always check the manufacturer’s flow chart for actual output at your required height. If you need 100 gallons per hour of flow three feet above the pump, a pump rated at 100 GPH maximum won’t deliver that. Consult the flow charts to verify the pump can maintain 100 GPH at three feet of head. Matching pump output at the actual head height is the only way to properly size an aquarium water pump.

If you’re going to push water through a pressurized filter system, consider using a slightly over-sized pump. As the filter begins to clog the extra pump capacity can compensate for clogging.

How Many GPH Does Your Aquarium Need?

The standard guideline for aquarium water pump sizing is based on tank volume turnover rate. Freshwater community tanks need the full tank volume cycled approximately 4 times per hour. Planted freshwater tanks benefit from 4–6 turnovers per hour for better nutrient distribution. Reef tanks require significantly more flow — 10 to 20 times the tank volume per hour — to keep corals healthy and prevent dead spots.

Recommended Flow Rates by Tank Size

Account for Head Loss

These flow rates represent what the pump should deliver at the point of use, not the pump’s maximum rating. A pump rated at 300 GPH at zero head may only deliver 200 GPH after accounting for tubing, fittings, and vertical lift. Always check the manufacturer’s flow chart at your actual head height.

Troubleshooting Common Aquarium Pump Problems

Even well-built aquarium water pumps develop issues over time. Recognizing the symptoms early prevents bigger problems like equipment failure or livestock stress.

Reduced Flow Rate

Aquarium water pump flow decreases gradually as debris accumulates inside the pump head and on the impeller. Calcium and coralline algae buildup is especially common in saltwater setups. Disassemble the pump and soak the impeller and housing in a 50/50 white vinegar and water solution for several hours, then scrub with a small brush. Check the intake screen for blockages too — a clogged intake starves the pump of water and reduces output.

Rattling or Chattering Noise

A rattling aquarium pump usually indicates a worn or cracked impeller, or an impeller that has shifted on its shaft. Impellers are wear items — the ceramic shaft and rubber bushings degrade over time. Most pump manufacturers sell replacement impellers for their models. A new impeller typically restores the pump to like-new performance and is far cheaper than replacing the entire pump.

Pump Runs but No Water Flows

An aquarium water pump that runs without moving water is usually air-locked. Air trapped inside the pump head prevents the impeller from grabbing water. Submersible pumps can air-lock if the water level drops below the intake. Tilt the pump underwater to release trapped air, or briefly disconnect and reconnect the output tubing to bleed the air pocket. External pumps may need to be primed by filling the intake line with water before starting.

Excessive Heat Transfer

Aquarium water pumps that run hot transfer that heat directly into the tank water. AC pumps generate more heat than DC pumps, and oversized pumps running at full power in small tanks can raise water temperature by several degrees. If heat is an issue, consider switching to a DC pump with adjustable speed — running at 60–70% power significantly reduces heat output while still providing adequate flow. An aquarium chiller may also be necessary for temperature-sensitive species.

When to Replace vs. Repair

Replace an aquarium water pump if the motor hums but the impeller doesn’t spin, if the pump trips a GFCI outlet repeatedly, or if the housing is cracked. Electrical faults and housing damage cannot be safely repaired. For worn impellers, clogged intakes, and reduced flow, cleaning or replacing the impeller is usually sufficient.

Checklist for Selecting an Aquarium Water Pump

Selecting the right aquarium water pump starts with understanding your specific flow requirements. By matching the pump to your tank’s needs, you avoid selecting a pump that disappoints. Compare several similar models and check the warranty — high-quality water pumps come with at least a one-year warranty. Some aquarium pump manufacturers even stock repair parts so you won’t have to buy a new water pump if a single component wears out.

Pump Selection Checklist

- Determine if the water pump will be used externally or submerged

- Measure where the water pump will be mounted or submerged

- Determine the desired flow rate and height you plan to lift the water

- Compare pump dimensions and flow rates at the desired head height

- Decide if you want a DC pump with wired or wireless control

- Compare warranties of similar water pumps

- Select the water pump that fits these specifications

What is the difference between direct drive and magnetic drive pumps?

Direct drive pumps physically connect the motor shaft to the impeller via a shaft seal, making them ideal for high-pressure applications like pushing water through large filter systems. Magnetic drive pumps use magnets to spin the impeller without a direct connection, eliminating the risk of shaft seal leaks and making them popular for general aquarium use.

Are DC pumps better than AC pumps for aquariums?

DC pumps offer several advantages over AC pumps. They use less electricity, run cooler, allow precise flow rate control via apps or control pads, and enable natural flow patterns like tides and waves. They also feature soft start-ups that prevent the chattering noise common with AC pumps.

How do I calculate the right pump size for my aquarium?

Look at the pump's flow rate at your required head height, not just the maximum rating. If you need 100 GPH at three feet above the pump, check the manufacturer's flow chart to ensure the pump delivers that rate at that height. Consider oversizing slightly if pushing water through pressurized filters.

What is 'head' in pump specifications?

Head refers to the resistance created by pumping water uphill. As height increases, the pump works harder against gravity and pipe friction, reducing actual flow rate. Always consult flow charts showing actual GPH at different head heights rather than relying on maximum flow ratings.

Can I use a submersible pump externally?

Some newer DC pumps are designed for both submersible and external use. They come with friction slip-fittings for PVC pipe and adapters for easy external hookup. However, traditional submersible pumps must remain submerged, and external pumps should never be exposed to water spray or drips.

How many GPH do I need for my aquarium?

Freshwater community tanks need approximately 4 times the tank volume per hour — so a 20-gallon tank needs 80–120 GPH. Planted tanks benefit from 4–6 turnovers per hour. Reef tanks require 10–20 times the tank volume per hour. Always check the pump's flow rate at your actual head height, not the maximum rating.

Why is my aquarium pump making noise?

A rattling or chattering aquarium pump usually has a worn or cracked impeller, or an impeller that has shifted on its shaft. Impellers are wear items that degrade over time. Replacing the impeller typically restores quiet operation. AC pumps may also chatter during start-up because the magnetic impeller can spin in either direction when AC current is applied.

How do I clean an aquarium water pump?

Disassemble the pump and soak the impeller and housing in a 50/50 white vinegar and water solution for several hours. Scrub with a small brush to remove calcium, coralline algae, or debris buildup. Check the intake screen for blockages. Reassemble and test — most pumps return to full flow after a thorough cleaning.

How long do aquarium pumps last?

Quality aquarium water pumps typically last 3–5 years with regular maintenance. The impeller is usually the first component to wear out, and most manufacturers sell replacement impellers. Cleaning the pump every few months and replacing the impeller when flow drops extends the pump's lifespan significantly.

What is the difference between a powerhead and a water pump?

A powerhead is a type of submersible water pump designed specifically for internal water circulation within the aquarium. Standard water pumps (return pumps) move water between locations — from a sump back to the tank or through a filter. Powerheads create flow patterns inside the tank for corals, plants, and debris suspension. Newer DC wave makers are an evolution of the traditional powerhead with programmable flow modes.

Should I run my aquarium pump 24/7?

Yes, aquarium water pumps should run continuously. Fish, beneficial bacteria, and corals depend on constant water flow for oxygen, waste removal, and nutrient delivery. Turning off the pump — even for a few hours — can cause oxygen levels to drop and allow ammonia to build up. The only exception is brief feeding modes on DC wave makers, which pause flow for a few minutes during feeding.

Do aquarium pumps use a lot of electricity?

Most aquarium water pumps use relatively little electricity. A typical DC return pump for a 50-gallon tank draws 10–30 watts — roughly the same as a small LED light bulb. AC pumps use more power than DC pumps for the same flow rate. DC pumps running at reduced speed use even less. Annual electricity cost for a mid-size aquarium pump is usually under $20.

Can an aquarium pump be too powerful?

Yes, an oversized aquarium water pump can stress fish by creating currents too strong to swim against, uproot plants, blast sand substrate, and prevent corals from extending their polyps. Signs of excessive flow include fish constantly hiding or struggling, and substrate being pushed to one side. DC pumps with adjustable flow solve this problem by letting you dial the output down to the right level.

Related Topics

Found this helpful?

Share this guide with your fellow aquarium enthusiasts!

Written by

FTW Team

The FishTankWorld editorial team brings together experienced aquarists to help you succeed in the hobby.