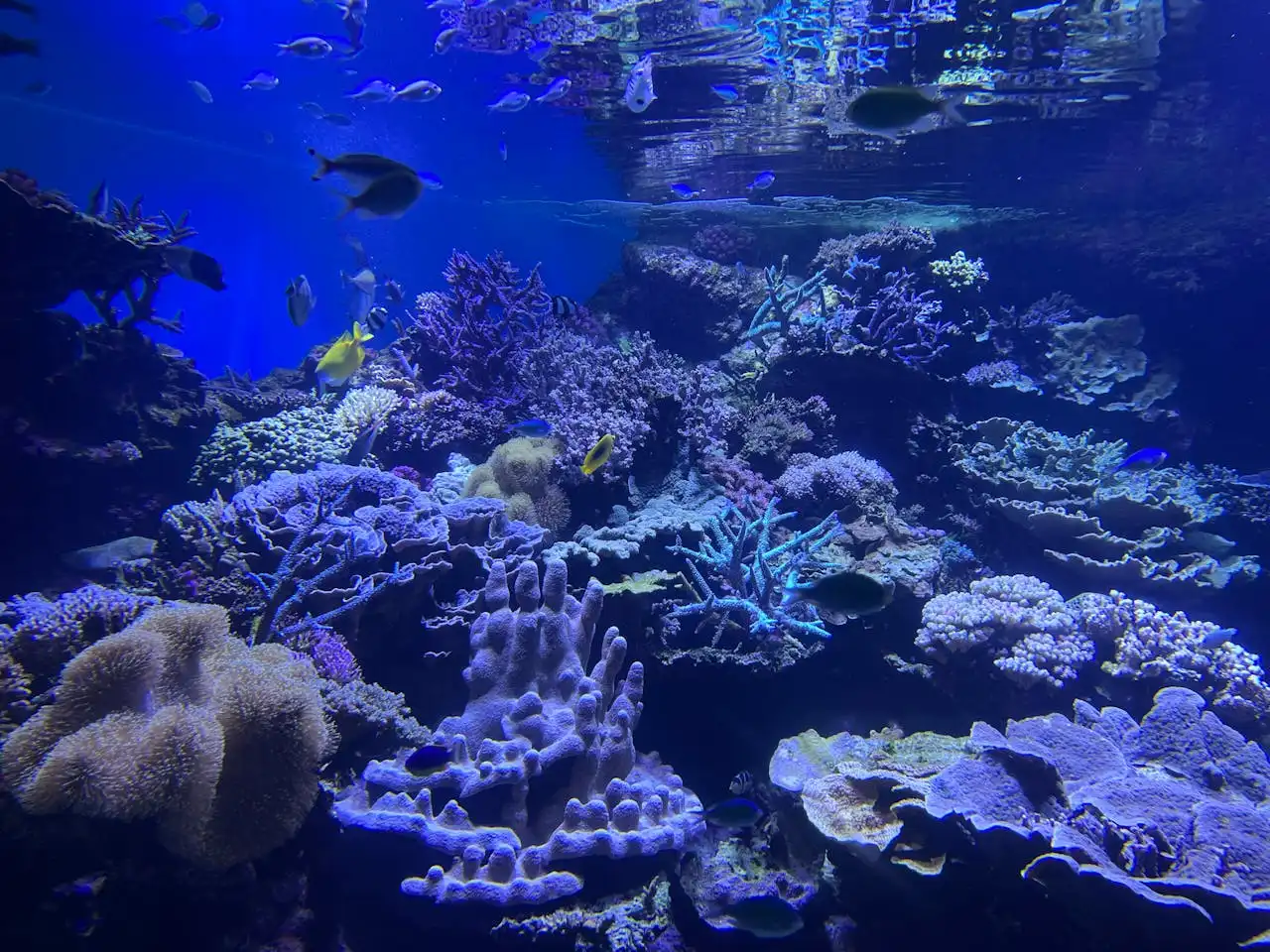

Maintaining stable calcium and alkalinity levels is one of the biggest challenges in reef keeping. A calcium reactor automates this process by continuously dissolving calcium-rich media and returning it to your aquarium, making it essential equipment for reef tanks with demanding corals.

Why Corals Need Calcium

Stony corals (LPS and SPS) secrete calcium carbonate to form their skeletal structures. In reef tanks, calcium and carbonate (alkalinity/KH) levels must be monitored and maintained so corals have adequate “building materials” to create the reef. Regular testing with a quality test kit helps you stay on top of these parameters.

How Calcium Reactors Work

A calcium reactor uses CO2 to dissolve calcium-rich media, releasing both calcium and alkalinity into your aquarium water in balanced proportions:

Calcium Reactor Process

Media Chamber

The reactor contains granular aragonite (calcium carbonate-based media) as the calcium source.

CO2 Injection

Carbon dioxide gas is injected to create acidic conditions (pH 6.5-6.8) inside the reactor.

Media Dissolution

The acidic environment dissolves the aragonite, releasing calcium and carbonate ions into the water.

Effluent Return

Calcium-rich water (effluent) drips back into the aquarium or sump at a controlled rate.

Automated Control

Advanced systems use pH controllers with solenoid valves to automate CO2 injection based on reactor pH.

This closed-loop process means the reactor continuously replenishes what your corals consume, with minimal intervention once dialed in.

Calcium Reactors vs. Alternatives

Calcium reactors aren’t the only way to maintain calcium and alkalinity. Here’s how the main supplementation methods compare:

| Method | Best For | Upfront Cost | Ongoing Cost | Complexity |

|---|---|---|---|---|

| Calcium Reactor | SPS-heavy tanks, 50+ gal | High ($200-500+) | Low ($40-60/yr) | Moderate-High |

| Two-Part Dosing | Mixed reefs, any size | Low ($30-60) | Medium ($80-200/yr) | Low |

| Kalkwasser (Limewater) | Top-off supplementation | Low ($20-40) | Low ($20-40/yr) | Low-Moderate |

| Dosing Pump + Solutions | Precise automated dosing | Medium ($100-300) | Medium ($80-200/yr) | Low-Moderate |

Calcium Reactor

SPS-heavy tanks, 50+ gal

High ($200-500+)

Low ($40-60/yr)

Moderate-High

Two-Part Dosing

Mixed reefs, any size

Low ($30-60)

Medium ($80-200/yr)

Low

Kalkwasser (Limewater)

Top-off supplementation

Low ($20-40)

Low ($20-40/yr)

Low-Moderate

Dosing Pump + Solutions

Precise automated dosing

Medium ($100-300)

Medium ($80-200/yr)

Low-Moderate

When to Upgrade to a Reactor

If you’re spending more than 30 minutes per week on manual two-part dosing, or your coral consumption outpaces what dosing can keep up with, a calcium reactor is likely worth the investment. Most reefers find the crossover point around 50-75 gallons with moderate to heavy SPS coral populations.

Two-part dosing (separate calcium and alkalinity solutions added on a schedule) is the simplest starting point for most reef keepers. It works well for smaller tanks and lighter coral loads but becomes expensive and time-consuming as demand grows.

Kalkwasser (calcium hydroxide mixed into top-off water) is an economical supplement that also helps maintain pH. However, it can’t supply enough calcium for heavy SPS systems on its own and requires careful mixing to avoid precipitation.

Dosing pumps automate two-part dosing, eliminating the manual labor. They’re simpler to set up than a calcium reactor but still require regular solution refills. For reef keepers who are new to saltwater aquariums, a dosing pump is often the first step toward automation before graduating to a reactor.

What to Look for When Shopping

When evaluating calcium reactors, focus on these key criteria:

Buying Criteria

- Tank size rating — match the reactor's rated capacity to your aquarium volume and coral load

- Media capacity — larger chambers mean less frequent refills; look for at least 1 gallon for tanks over 100 gallons

- Pump type — integrated DC pumps offer convenience and variable flow; external pump setups cost less but add complexity

- Controller compatibility — APEX and other aquarium controller support allows automated pH monitoring and CO2 shutoff

- Build quality — acrylic construction should be thick and well-bonded; check that O-rings and fittings are included

- Secondary chamber — some reactors include a second stage that further dissolves media and helps off-gas CO2 before effluent returns to the tank

What You’ll Need

In addition to the calcium reactor itself, you’ll need supporting equipment:

Required Equipment

- CO2 cylinder and regulator with solenoid

- Aragonite or calcium carbonate media

- Feed pump (if not integrated)

- pH probe and controller (optional but recommended)

- Tubing and fittings for connections

Automation Recommended

While manual calcium reactors work, a pH controller with solenoid valve dramatically simplifies operation. The controller maintains optimal reactor pH automatically, preventing over- or under-dosing that can harm corals.

Conclusion

A calcium reactor is one of the most effective ways to maintain stable calcium and alkalinity in a reef aquarium. While the upfront investment is higher than two-part dosing, the reduced ongoing costs and hands-off operation make it the preferred choice for serious reef keepers with demanding coral populations.

Start by establishing your tank’s calcium consumption rate with regular testing using a reliable test kit. Once you know your daily demand, you can size and tune a reactor to match — and spend less time dosing and more time enjoying your reef.

What does a calcium reactor do?

A calcium reactor dissolves calcium carbonate media (aragonite) using CO2 injection to create acidic conditions. This releases calcium and alkalinity (carbonate) into the water, providing the building blocks corals need to grow their calcium carbonate skeletons.

Do I need a calcium reactor for my reef tank?

Calcium reactors are most beneficial for tanks with high coral demand, especially SPS-dominant systems. Smaller tanks with few corals can often maintain calcium through water changes and two-part dosing. A calcium reactor becomes worthwhile when manual dosing becomes time-consuming or expensive.

What's the difference between calcium reactors and dosing pumps?

Calcium reactors use CO2 to dissolve media and provide both calcium and alkalinity automatically. Dosing pumps add separate calcium and alkalinity solutions. Reactors have higher upfront cost but lower ongoing expense; dosing is simpler to set up but requires solution refills.

How do I set up a calcium reactor?

Basic setup involves connecting a feed pump, CO2 regulator with bubble counter, and effluent line to your sump. Fill with aragonite media, adjust CO2 to achieve pH 6.5-6.8 in the reactor, and set effluent drip rate based on tank demand. A pH controller automates CO2 injection.

How much does it cost to run a calcium reactor?

After the initial equipment investment, ongoing costs include CO2 refills (roughly $15-25 every few months depending on tank size) and replacement media ($20-40 per refill, needed every 3-6 months). This is generally cheaper than two-part dosing solutions for tanks with heavy coral loads.

Can a calcium reactor lower my tank's pH?

Yes. Because the reactor's effluent has a low pH (6.5-6.8), dripping it too fast into the aquarium can suppress tank pH. A secondary chamber or dripping effluent into a high-flow area of the sump helps off-gas excess CO2 before it enters the display tank.

Related Topics

Found this helpful?

Share this guide with your fellow aquarium enthusiasts!

Written by

FTW Team

The FishTankWorld editorial team brings together experienced aquarists to help you succeed in the hobby.